|

|

APPLICATION

The challenges facing farms, milk collectors and the dairy industry

• Maintaining the quality of raw milk during transport

• Maintaining the quality of raw milk during storage

• Maintaining the quality of raw milk during all seasons

SE-CU™ DAIRY APPLICATION

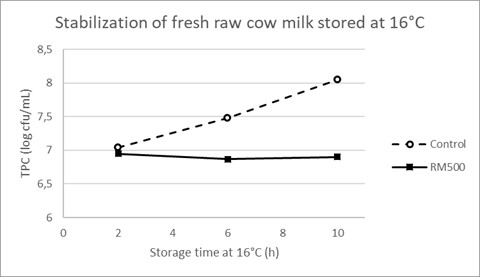

SE-CU™ RM500

SE-CU™ RM500 can offer a solution to these challenges

• Optimizing the basic quality of the end products

CHALLENGES

The challenges facing the dairy industry

• Left-over culture activity

• Environmental spoilage

• Spoilage of the raw material

• Changes in characteristics

• Spoiled brine / pack water

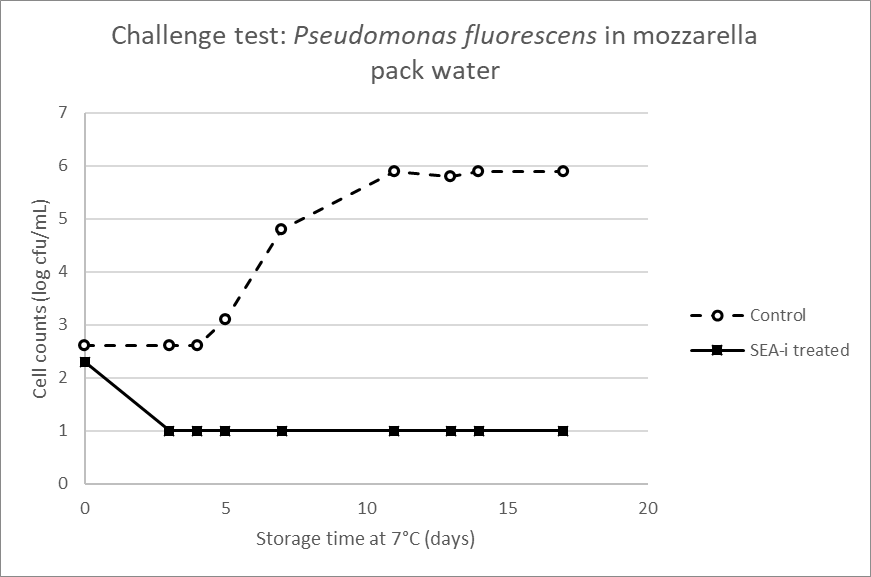

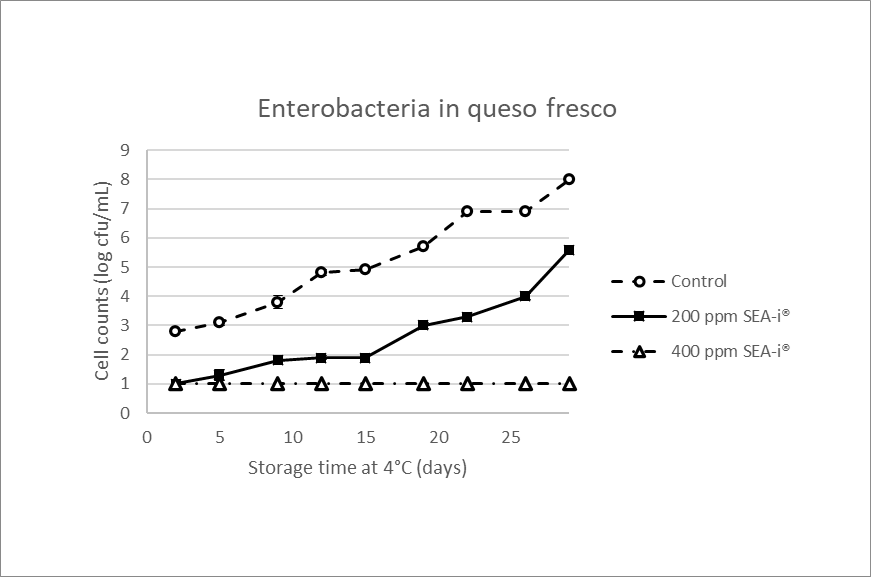

SEA-i®

SEA-i® can offer a solution to these challenges

• Preventing turbid pack water / brine

• Maintaining original characteristics

• Extension shelf life

• Optimization of global quality

SEA-i® DAIRY APPLICATION

SEA-i® DAIRY APPLICATION